ACO Recycling is at the forefront of developing solutions and instruments for deposit return and reward systems.

Over the last numbers DRS systems have evolved to meet the social and economic requirements of society by encouraging public participation in recycling in public spaces.

By encouraging a tangible incentive, DRS has effectively changed consumer behaviour leading to cleaner environment, sustainable and cost-efficient waste management.

The ACO DRS is supported by a comprehensive V5 platform to manage all operations such as fullness monitoring, bottle process flow, value analysis and unit access.

The system can operate both online and offline, with a robust security solution.

The platform enhances collection efficiency and incorporates ACO 360° user behaviour analysis to gather valuable big data, providing deeper insights and optimising your recycling strategy.

Immerse in the large interactive 21.5inch touch display, offering a clear and engaging user experience

Local Time / Date & Weather to keep users informed directly on the display.

User-friendly interface which allows easy navigation though the intuitive design which is recognised for its simplicity and efficiency.

Changeable logo/branding ensures that the machine is always aligned with your current environment or promotional campaigns.

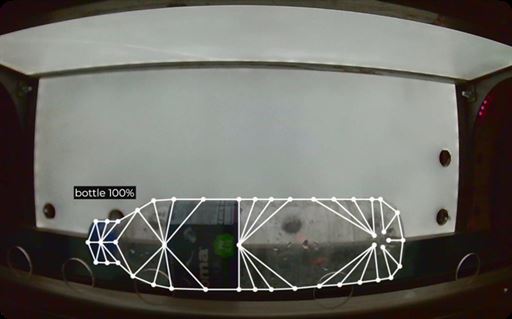

ACO Recycling use AI based photo recognition technology and/or custom 360 degree barcode recognition technology combined with weight recognition.

Thermal printer prints out vouchers, or integration to external card reader systems, integration to external API and APP online reward model integration.

Lan or 4G Router

Up to 3L

K-3 Reverse Vending machine, is ideal for high traffic areas due to its robust , standalone design. Its compact yet boasts modular capabilities for diverse DRS. Engineered for busy environments, it features advanced recognition capabilities for high accuracy, rapid item processing speeds.

19 Variations available to meet your needs

– Crusher, Shredder, Sorting Modules

– Basic Drop, Sorting Modules

– Basic Drop Modules

– Crusher Modules

Copyright 2024 MEAHA All rights reserved.